01

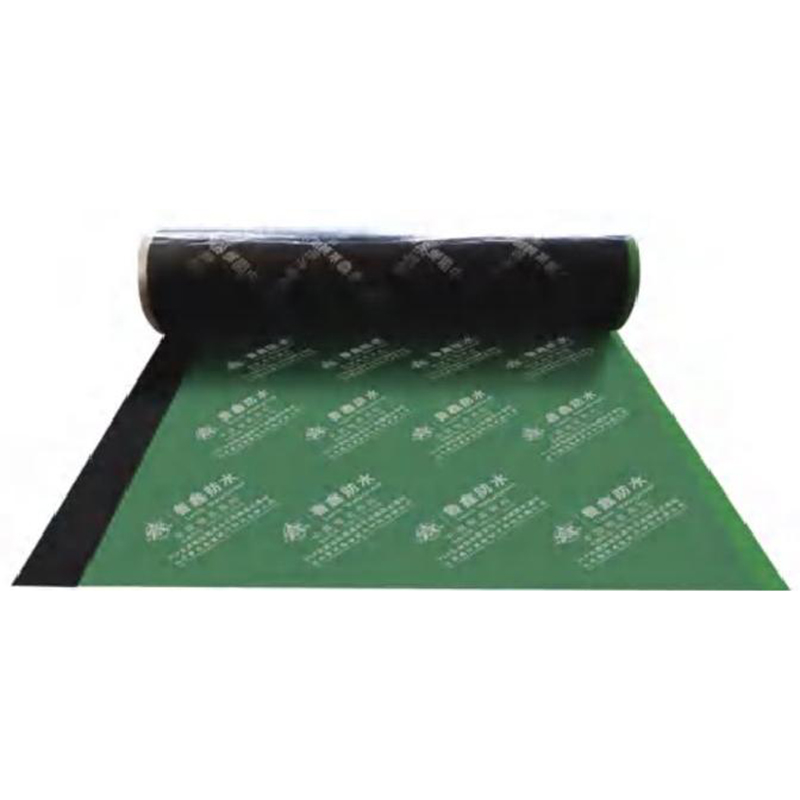

LX-Brand polymer reaction adhesive wet adhibiting membrane

description2

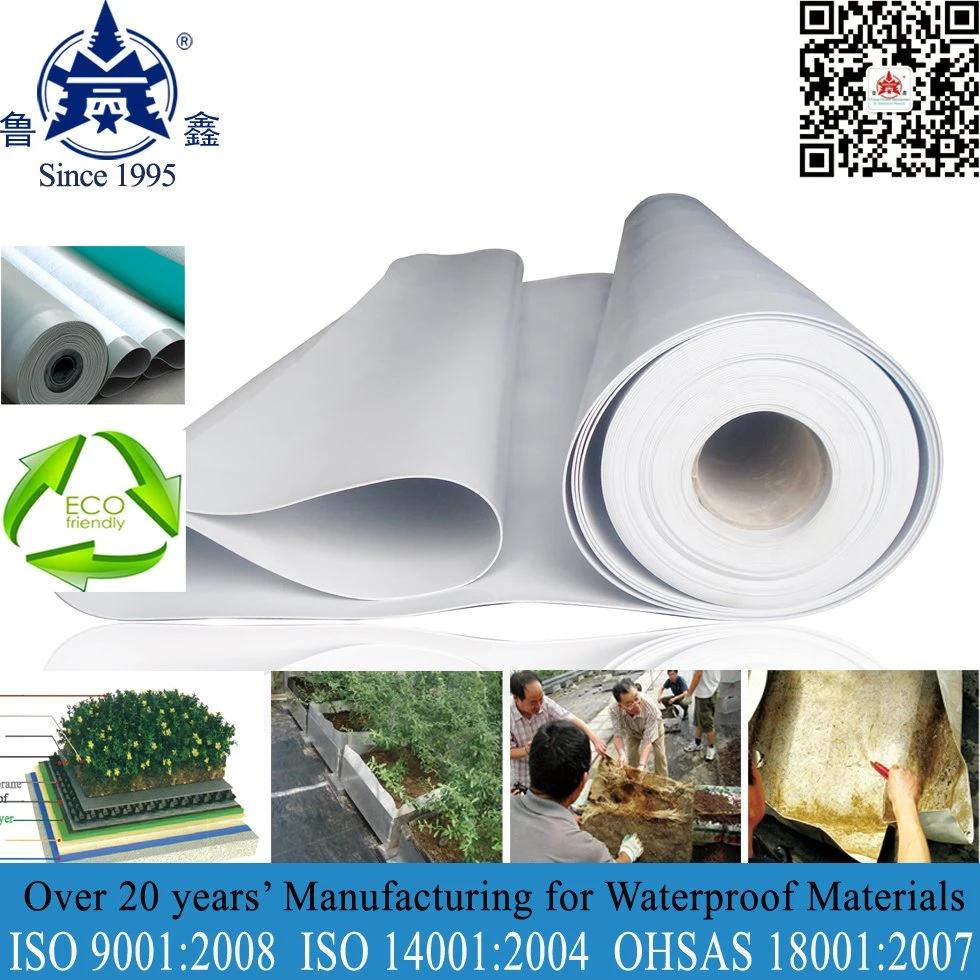

Application

Apply to the following works:roofs of industrial/civilian buildings, basements, toilets, roads, bridges, tunnels, channels, grain depots, swimming pools, tanks, waste landfills, sewage works, irrigation/drainage works, city greening patches, planting roofs, log cabin, repairing of old roofs and steel frameworks etc.

description2

Working key points

1. Wet adhibiting method: Clean the substrate-ready cement mortar-detailing trimming-pre-lay membrane- coat cement mortar-pave the membrane-get rid of the air-making compaction-overlap trimming-overlap/edge /seam sealed-protection layer.

2. Dry adhibiting method:Clean the substrate-coat primer-detailing trimming-pre-lay membrane-pave the membrane-get rid of the air-making compaction-overlap trimming-overlap/edge /seam sealed-protection layer.

Remove the isolation layer completely, adhibit the membrane after the primer dry,for the overlap part, necessary hot air welding is required,especially at a low temperature condition. The merit of dry adhibiting method is helpful to the self-sealing for the contract,tilting crack caused by external force;in case adhibiting is to be done on vertical substrate or steep slope,in order to prevent the sagging/sliding,and get a tight bonding effect between the membrane and the substrate,hot air torching is required as an auxiliary measurement,or metal batten fixing where is necessary.

The proper working temperature ranges from +5°℃ to +30°℃,working in rainy/stormy/ snowy/strong sunshine condition is forbidden;the substrates should be smooth,clean and no ponding ;for the joint of pipe,inside and outside corners,deformation joints, special reinforced measurements should be given. Keep nice ventilation after working finished,non workable on the cement mortar before completely dry;the following up working should be done till the cement mortar dry completely.