010203

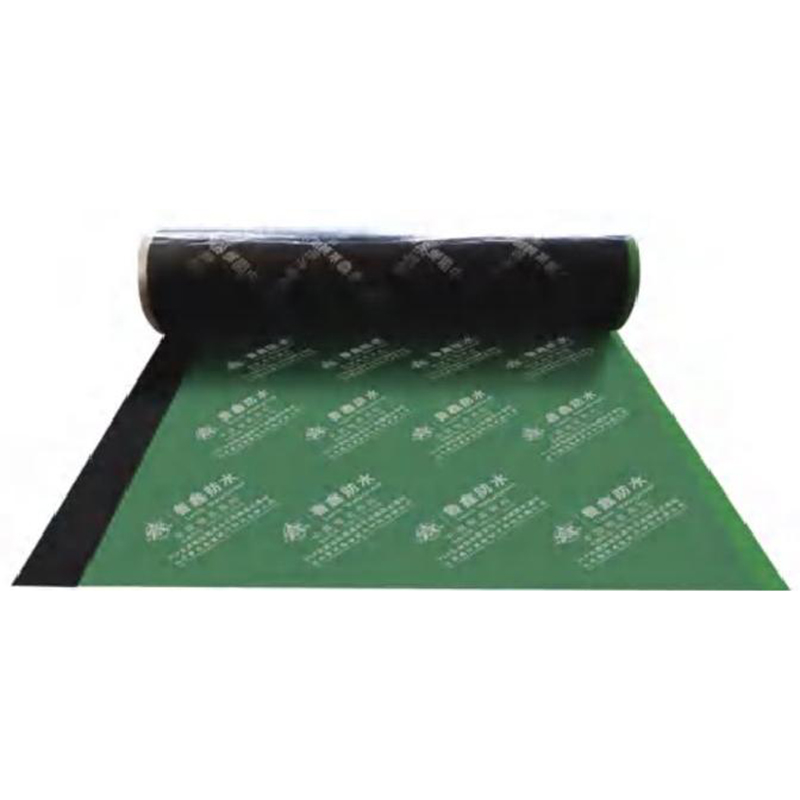

LX-Brand root-penetration resistance modified bitumen waterproof membranes

description2

Characteristics

Different specifications/types of membranes to be stacked and stored separately,and the storage temperature is no more than +50degree Celsius;

During transportation,the membranes should be placed vertically and no more than 2 layers;to avoid leaning and cross heap-up,tarpaulin is needed wherever possible;

Keep away from rain/sunshine/fire,stored in well ventilating warehouse.Under normal transportation/storage conditions,the shelf life is 1 year from the date of manufacture.

description2

Working key points

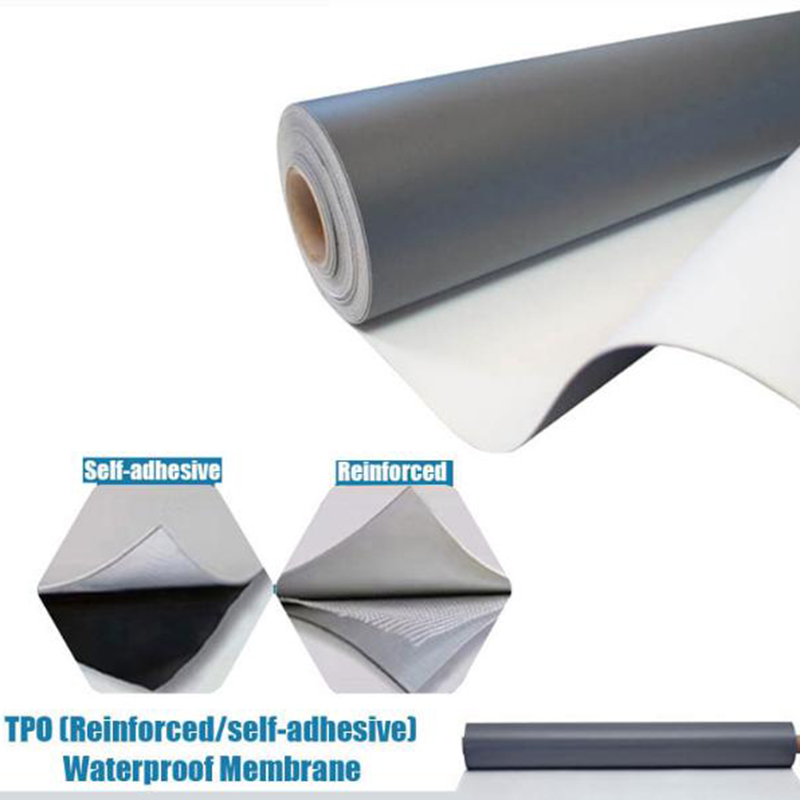

Membrane adhibiting method:

1.You can choose one from the following 3 methods: hot melt adhibiting,cold adhibiting,or hot melt adhibiting combines with cold adhibiting method,i.e. for main part of the membrane,cold adhibiting adopted,while for the overlaps,hot melt adhibiting adopted.

2.Hot melting:to heat the substrates or the back surface by torcher or other heater evenly,when the bitumen begins to melt and show shining black color,you can adhibit the membrane with continuous heating,and meanwhile compact the membrane by rubber roller;adjust the flame to the suitable status,and keep the temperature around 200-250 degree Celsius,after finishing the adhibiting of membrane,then seal the overlaps with cold adhesive/sealant.

3.Cold adhibiting :to pre-coat bitumen primer on the substrates with even thickness,wait a moment and till the primer dryer,and then adhibit the membrane,meanwhile,compact the membrane by rubber roller;in case the temperature down to 15 degree Celsius,heat melting is required to seal the overlap /edge /end.

Re:Trimming on the overlap position:In case single-layer membrane adhibited and there exists a longer overlap,the longitudinal overlap width should be more than 10cm,transverse overlap width should be more than 15cm;in case double-layer membrane adhibited,the longitudinal overlap width should be more than 8cm, transverse overlap width should be more than 10cm.The overlap parts must be adhibited firmly,any ignorance of no heating or no primer coating is not allowed;heating and make sure a little extra melting bitumen exuded to close up the edge or much more cold adhesive /sealant to seal the edge.

Working tools and accessories: Spade,broom,dust blower,hammer,chisel;Scissors,band tape,neat line box,scraper,brush,roller.Single head or multi-head torcher /heater. Primer,sealant for edges,compression strips for ends.

description2

Membrane adhibiting

The surface of the substrate must be smooth,clean,dry,moisture content should be less than 9%,to pre-coat bitumen primer on the substrates with even thickness,wait a moment and till the primer dryer,and then adhibit the membrane;reinforced waterproofing protecting layer/treatments should be done to the joints/edges /ends where necessary.

As per the neat line to make sure the adhibiting sequence and direction,pay special attention to the following requirements:

1.For roof adhibiting:The membrane should be laid in dotted adhibiting or in banded adhibiting;fullly adhibiting should be done at least 80cm from the edge of the roof; for the inclined roof the adhibiting ration should be more than 70%,while fully adhibiting is required between the upper and beneath membranes.

2.For basement floor:the adhibiting between the membrane and the substrate,you can take dotted adhibiting/fully adhibiting/banded adhibiting/border adhibiting,however,fully adhibiting method is rquired between the upper and beneath membranes.

3.For the vertical wall of the basement,fully adhibiting method should be taken;

4.For the regular reinforced parts,fully adhibiting method is required,whereas for the deformation joints, border adhibiting method acceptable.