01

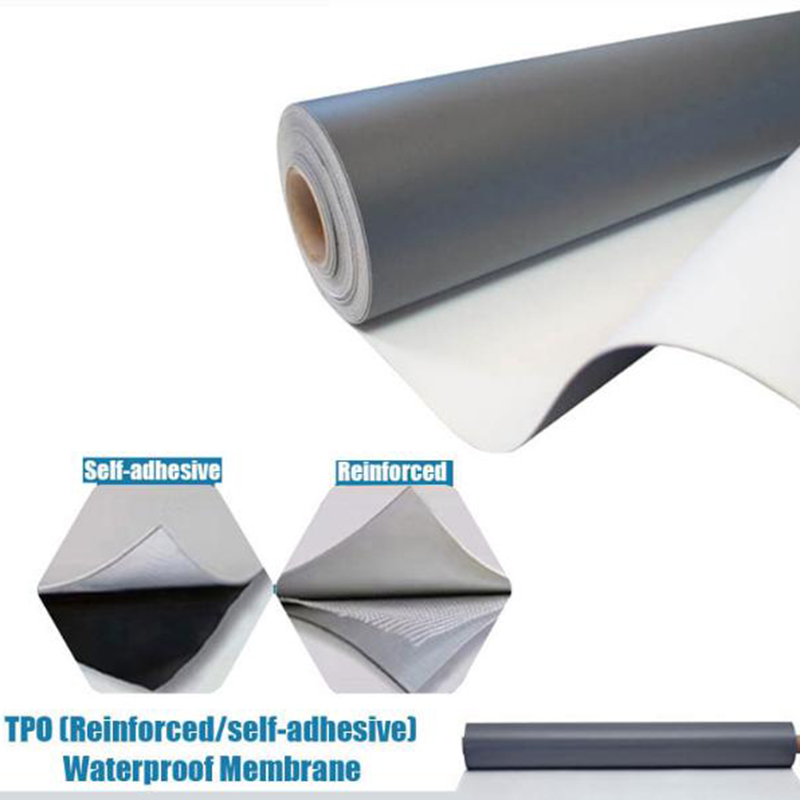

LX-Brand thermoplastic polyolefin (TPO) waterproof membrane

description2

Characteristics

Good combination of high elasticity and tensile strength.

Fine resistance to static electricity.

Excellent resistance to ageing & weather ability.

Fine flexibility at low temperature.

description2

Working key points under mechanical fixing method waterproofing system.

The substrate must be clean, smooth,dry, no peeling, no crack, no flake; all the ice,ponding,snow,debris and other foreign substances must be cleared away. Before laying/installing the membrane as per the neat line/datum line,you must ensure that the membrane is smooth,flat, too much tenseness is forbidden.

description2

The fixing around the edge of the waterproofing works:

The distance/gap between each fixing point should depend on the local wind speed,structure of the works,the height of the works and the width of the membranes. The max distance should be less than 600mm, and the TPO membrane should be adhibited by fully adhibiting method at least 800mm to the edge of the works, moreover, at the area of the rise and fall, side wall, skylight, deformation joint and the inside corners which slope more than1/6, the joint of the pipe and hoop groove, special reinforced fixing required.

Hot air welding:

To use automatic/hand-held hot air welder and silicone rubber roller, hot air welding and press the membrane to keep compression simultaneously.